How safe are enzymes?

Enzymes are:

- Biedegradable

- Non-bacterial

- Non-hazardous

- Non-toxic

- Non-corrosive

- Non-flammable

Our enzymes are formulated to be incorporated into water at very low concentration levels and are therefore environmentally safe. All regulated components of our enzymes have been rigorously tested for human safety, biodegradability and aquatic safety.

How quickly will we see the results?

It doesn't happen overnight. A biological process takes time. Enzymes are not an instant answer, but are the lasting answer.

Enzymes will first soften any grease. Odours are treated more quickly – the bacteria in the system will produce odours while decomposing nutrients. Hydrogen Sulphide is the most infamous. Enzymes do not produce foul-smelling compounds. Instead, they use them in their unique metabolic process, thus an advantageous synergistic relationship is formed.

For how long are enzymes active?

Enzymes remain active for seven to ten days. After this time, the product will biodegrade and the residue will consist of carbon dioxide and water.

Is it safe to use around children and animals?

The product is safe for humans, animals and plant life as it contains no harmful chemicals. It is developed entirely from natural products found in our environment.

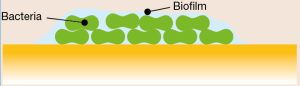

Information on Biofilm

Picture of Biofilm

Bacteria are smarter than you think

All bacteria have automatic mechanisms by which they adhere to surfaces and to each other.

They form communities and secrete a protective layer of biofilm around them as a defensive measure.

Hidden behind this protective layer, they are able to feed and multiply.

Biofilm – What you need to know

Biofilm is a collection of bacteria encased in extracellular polymeric substance (EPS), more commonly known as slime. This slime forms on surfaces and builds up over time, allowing pathogens to flourish and leading to contamination.

Many industrial companies struggle with biofilm. Build-up and subsequent contamination can occur on any type of surface, often including food production machinery, membrane filters, and pipes, to give just a few examples.

The slime is a problematic and unpredictable source of contamination that is very hard, if not impossible, to remove with traditional cleaning chemicals.

Although various methods are used to attempt to control biofilm, they are not without limitations. Aggressive chemicals such as caustic soda and bleach are often used, but they do not provide very good performance and, at the same time, corrode materials and machinery, endanger users, and negatively impact the environment.

Fortunately, a more efficient, safe, and environmentally friendly option is available – enzymes.

A two-step, Multi-enzyme method

Using an easy two-step cleaning procedure comprising a Multi-enzyme mix based on enzymes followed by a biocide step is an efficient way to rid surfaces of biofilm.

The enzymes act specifically on the EPS that forms the structure of the biofilm, degrading it and allowing the detergent to remove the biofilm. This enables the subsequent disinfectant step to reach all the way down to the exposed bacteria and kill them.

A complementary solution

Some companies are afraid that switching to this enzymatic solution will mean that they need to completely change their cleaning regimen, but this is absolutely not the case. Actually, the solution is complementary to a company's current cleaning procedure; it only needs to be used periodically to keep the biofilm under control.

Biofilm is notoriously difficult to deal with – Enzymes are the Solution